Manufacturing procedures of Karimoku60 furniture

Manufacturing

The armrest of the K CHAIR is shaped in rich and elegant curves and this is everything of the K CHAIR. After the shaping process by a Computer numerically controlled (CNC) router, the furniture makers attentively sand the armrest with sandpapers of 5 different grits with their skillful hands. Even though the wood is of the same species, It is very common to have variations in color, texture and natural markings and therefore it is very important for the furniture makers to streamline the shape with their unique touch towards the wood.

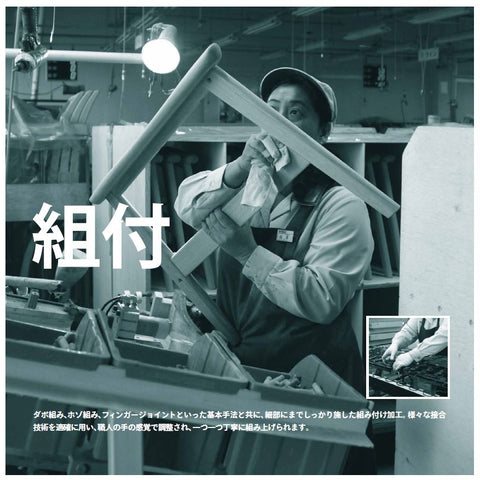

Assembling

Individual components are meticulously assembled with traditional woodworking techniques such as dowel joint, fingerjoint, mortise and tenon joint. The furniture makers use appropriate joint techniques at various connections to assemble the furniture caringly and subsequently make fine adjustments with their touch towards the furniture.

Coating

The furniture makers attentively applies coating on individual components and then dry them in the drying chamber. Another layer of coating will then be applied when the previous layer of coating has been dried completely. During this coating process, the wood fibre on the surface will become rough and has to be sanded and adjusted manually. In order to outstand and profound the natural wood grain, the coating and sanding process has be to carried out six times repeatedly.

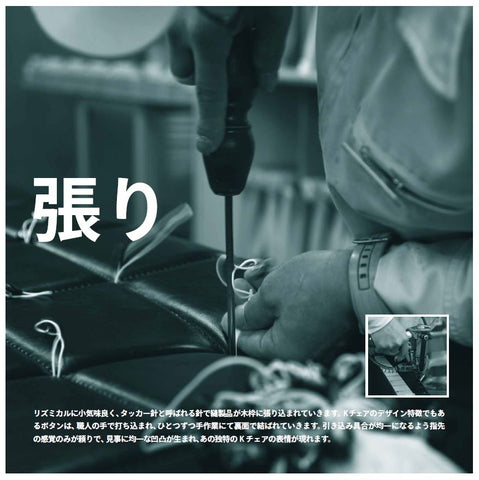

Upholstery

Following the vivacious rhythm, the furniture makers attach the upholstery to the wooden frame with a pleating tool (TUCKER). Upholstery buttons will then be sewed punctiliously to form the deep tufting, a signature design of the K CHAIR. With the accumulated know-how and touch of the finger, the furniture makers make the unique tufting pattern consistently and uniformly.

Inspection

In order to ensure the durability and consistent quality of the furniture, KARIMOKU sets a rigorous standard of quality and adopts every practicable means of quality checking to examine the furniture.

This is our imperishable value of being a wood-respecting furniture brand - If we are to use the Hundred-Year-Old tree to produce furniture, we hope to produce the furniture that deserves the Hundred-Year-Old year ring.